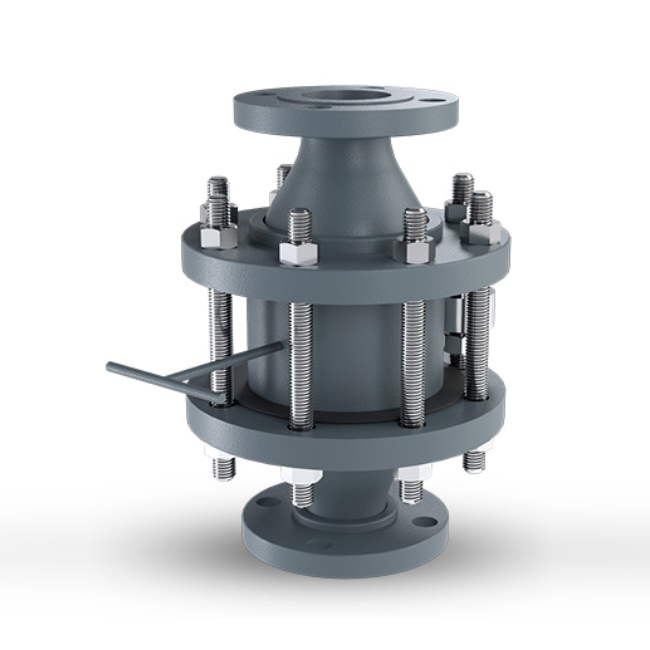

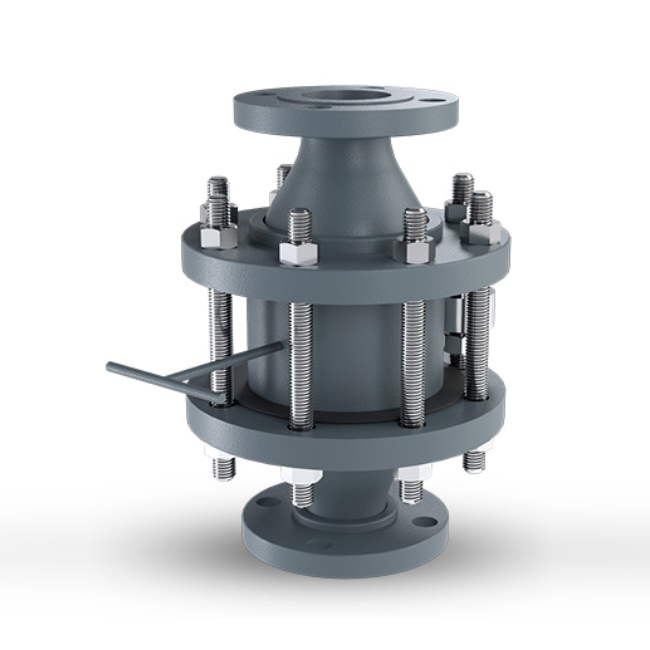

45000E/ 46000E Series In-Line Deflagration Flame Arresters, ATEX / CE / ISO

Protectoseal Series 45000E and 46000E In-Line Deflagration Flame Arresters are designed to withstand low, medium and high pressure deflagrations (subsonic). These arresters are bi-directional and capable of stopping a flame approaching from either direction in a piping system and can be mounted vertically or horizontally in the pipeline. Suitable for varying distances from the unprotected side of the vent pipe, maximum distance (Lu/D=50), and within determined operating pressure, consult factory for specifics. These arresters prevent confined deflagrations from passing the arrester and entering a protected area.

• Bi-directional design stops a flame approaching from either direction in a piping system

• Crimped metal arrester element minimizes pressure drops and reduces overall weight

• Straight through flow pattern minimizes arrester element fouling and simplifies the cleaning process

• Removable and interchangeable arrester element facilitates ease of inspection and maintenance

• High strength, welded steel housing hydrostatically tested at 235 PSIG

• Pressure retaining housing components are welded in accordance with ASME Pressure Vessel Code, Section IX requirements

Datasheet

Datasheet

| Sizes |

: |

45000E 2” (DN50) to 12” (DN300)

46000E 2” (DN50) to 4” (DN100) |

| Flange Connections |

: |

150# ANSI or DIN PN16 connections |

| Max. Initial Pressure |

: |

45000E – 1.1 – 1.3 bara (15.95 – 18.85 PSIA)

46000E – 1.1 – 1.6 bara (15.95-23.21 PSIA) |

| Max. Initial Temperature |

: |

60º C (140º F) |

| Housing Configuration |

: |

Concentric |

| Materials |

: |

Carbon Steel, Stainless Steel and Alloy C276 |

| Gas Groups |

: |

45000E – IEC Explosion Group IIA | NEC Group D

46000E – IEC / ISO Explosion Group IIA, IIB3 | NEC Group D, C |

| Testing & Certifications |

: |

Approved according to the latest ATEX Directive, ISO 16852 |

TR

TR

Datasheet

Datasheet

Dudullu OSB, İMES sanayi sitesi B Blok 204.sok No:11 Ümraniye /İstanbul

Dudullu OSB, İMES sanayi sitesi B Blok 204.sok No:11 Ümraniye /İstanbul  +90 216 365 05 54

+90 216 365 05 54  info@dekaproses.com

info@dekaproses.com