Safety Valve Testing & Maintenance Services

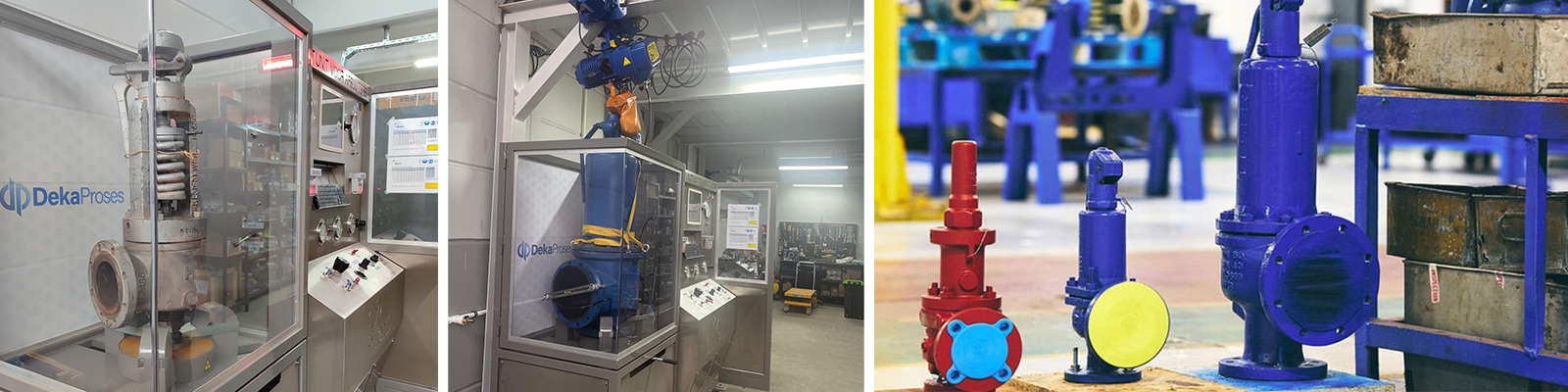

Safety valves (PSVs) are used in a wide range of industrial applications involving air/gas, steam, liquids, and liquid vapors. These pressure relief devices play a critical role in ensuring the safe operation of facilities across industries such as chemicals, petrochemicals, oil & gas, power, mining, and boiler systems. As the name suggests, these essential safety components are vital for protecting both your personnel and facilities.

External factors such as extreme temperatures, corrosive environments, improper operating conditions, oxidation, erosion, buildup, or mechanical damage can significantly impact the performance of safety valves. High temperatures may cause metal fatigue or deformation, while corrosive media can deteriorate valve components, rendering them ineffective.

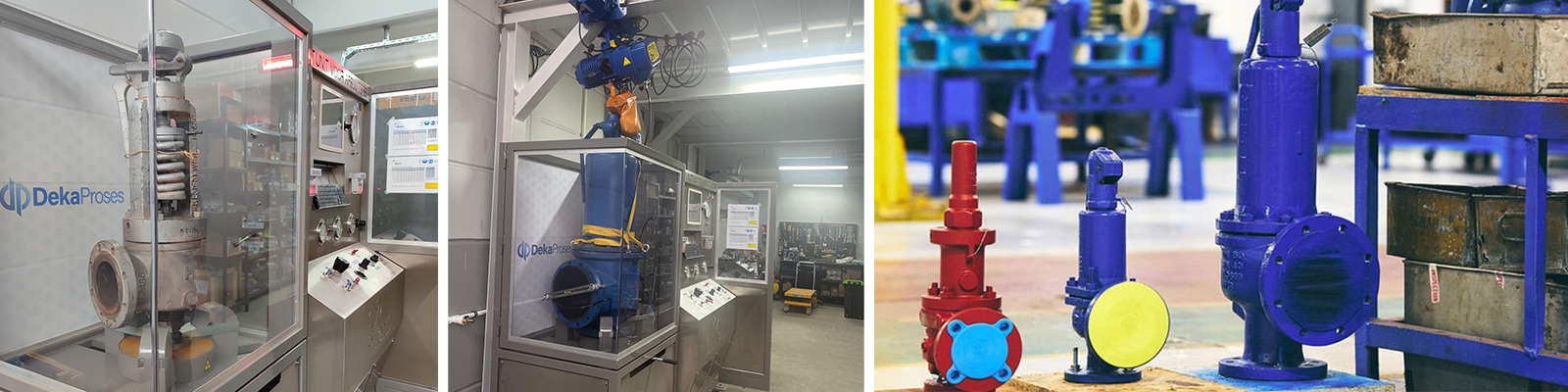

For this reason, periodic testing, maintenance, and calibration of safety valves is essential. With our experienced team and TÜV-certified test benches, we provide this service either in our workshop or on-site using our mobile testing units.

Using our TUV-certified portable test unit, we perform set pressure and leak tightness tests with water, nitrogen, or air (up to 10” diameter and 200 bar set pressure) in compliance with API and ASME standards. When maintenance is required, we perform lapping, polishing, sandblasting, surface cleaning, spare part replacement, painting, and other necessary procedures to restore valve functionality.

All test results are certified with high precision using specialized computer software.

We store historical test reports for many years in our cloud-based system, helping you track the long-term performance of your safety valves and build a reliable routine for periodic maintenance planning.

OUR SERVICES;

SAFETY VALVE TESTING AND MAINTENANCE IN OUR WORKSHOP

We service all brands and models of safety valves using state-of-the-art equipment to enhance the performance and reliability of your valves.

MOBILE SAFETY VALVE TESTING AND MAINTENANCE SERVICE

MOBILE SAFETY VALVE TESTING AND MAINTENANCE SERVICE

One of the preferred methods of on-site testing is to quickly remove the valve during short shutdowns, test it promptly, and reinstall it without significant downtime. With our mobile on-site testing service, you can reduce downtime while having the opportunity to observe the testing process directly.

Valves that do not pass the test are serviced upon customer approval. Operations such as lapping, gasket replacement, spring inspection, machining, and spare part replacement are carried out on-site.

Thanks to our TÜV-certified portable test equipment from Ventil, we have the capability to test your safety valves directly at your facility.

ONLINE SAFETY VALVE TESTING SERVICE

ONLINE SAFETY VALVE TESTING SERVICE

We test your safety valves while they are in operation—without removing them from the line—using our ATEX-certified online testing equipment. This method verifies the accuracy of the valve’s opening and closing (set pressure) values.

Online Pressure Safety Valve (PSV) testing and maintenance involve performing these operations directly at the client’s offshore or onshore facility. On-site testing allows for real-time assessment of PSV performance under actual operating conditions, enabling immediate adjustment or repair without the need for complex logistics or operational downtime.

This approach minimizes failure time and ensures the valves remain operational, reducing the impact on production processes. Detailed test reports are compiled and delivered to the client upon completion.

TR

TR

Dudullu OSB, İMES sanayi sitesi B Blok 204.sok No:11 Ümraniye /İstanbul

Dudullu OSB, İMES sanayi sitesi B Blok 204.sok No:11 Ümraniye /İstanbul  +90 216 365 05 54

+90 216 365 05 54  info@dekaproses.com

info@dekaproses.com