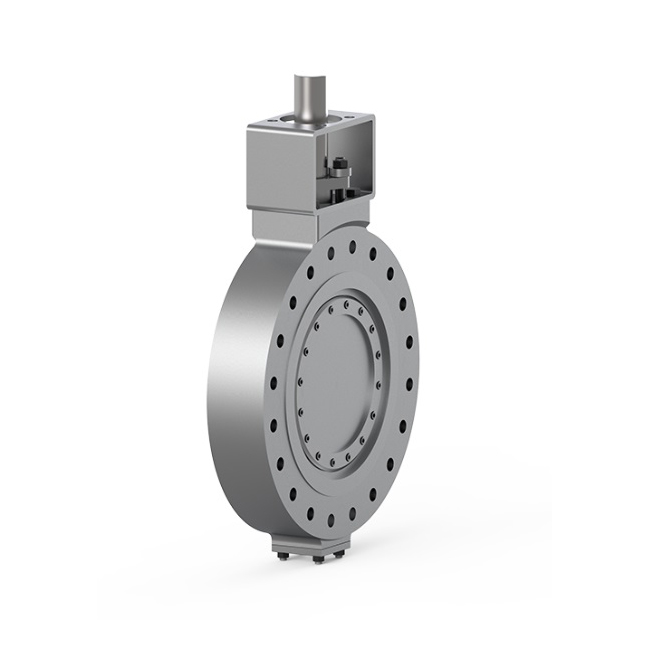

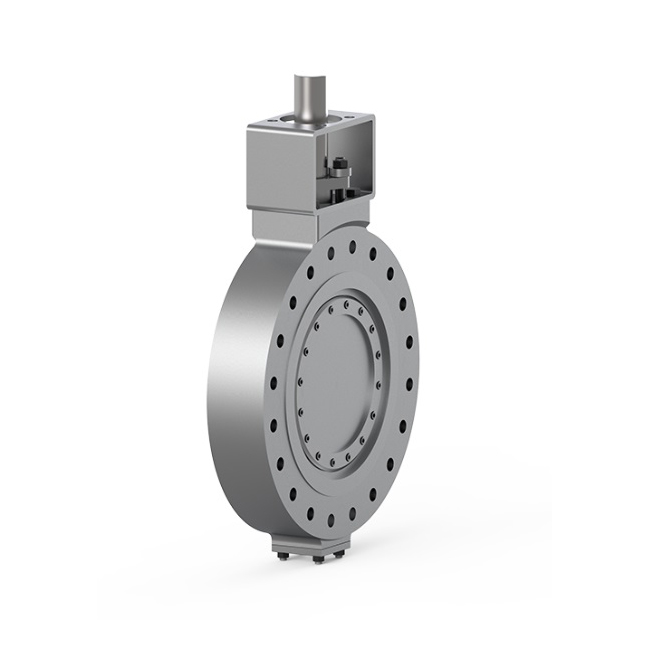

OG High Performance Triple Offset Butterfly Valves

OG, OHL Gutermuth’s latest generation series. This series combines features, functions, and versatile applications, and is especially economical. For example, OG Valves, which provide the highest operational reliability standards and a long service life under high pressures or dynamic loads, also offer excellent sealing, ranging from "very hot" to "very cold."

OG High-Performance Triple Offset Valves, specifically designed for critical applications, provide a far more reliable solution than conventional solutions from various angles. OHL Gutermuth supplies many different variations of these butterfly valves in terms of function, structure, and material, fully adapted to individual operational requirements. OG Butterfly Valves provide reliable and economical engineering for shut-off and control in energy plants, paper and chemical industries, petrochemical, gas industries, water and wastewater, oil and gas, refineries, iron and steel industries, sugar industry, shipbuilding, and plant construction sectors.

Applications for Triple Eccentric (three-axis) metal seat butterfly valves include: oxygen, gases, exhaust gases, liquids, abrasive, and corrosive fluids.

APPLICATION AREAS

» Energy plants

» Sugar industry

» Gas industry

» Paper industry

» Iron & Steel industry

» Mining

» Chemical industry

» Petrochemical / refineries

| Sizes |

: |

DN 80 – 600 / 3“ – 24“ |

| Pressure Range |

: |

PN 10-PN 50 / Class 150 – 300 |

| Temperature Range |

: |

-10°C – 450°C |

| Leakage Rate |

: |

EN 12266 Rate A / FCI 70.2 Class VI |

| Optional |

: |

Carbon Steel or Stainless Steel |

| Certificates |

: |

Fire Safe acc. to API607, BS6755 |

TR

TR

Dudullu OSB, İMES sanayi sitesi B Blok 204.sok No:11 Ümraniye /İstanbul

Dudullu OSB, İMES sanayi sitesi B Blok 204.sok No:11 Ümraniye /İstanbul  +90 216 365 05 54

+90 216 365 05 54  info@dekaproses.com

info@dekaproses.com