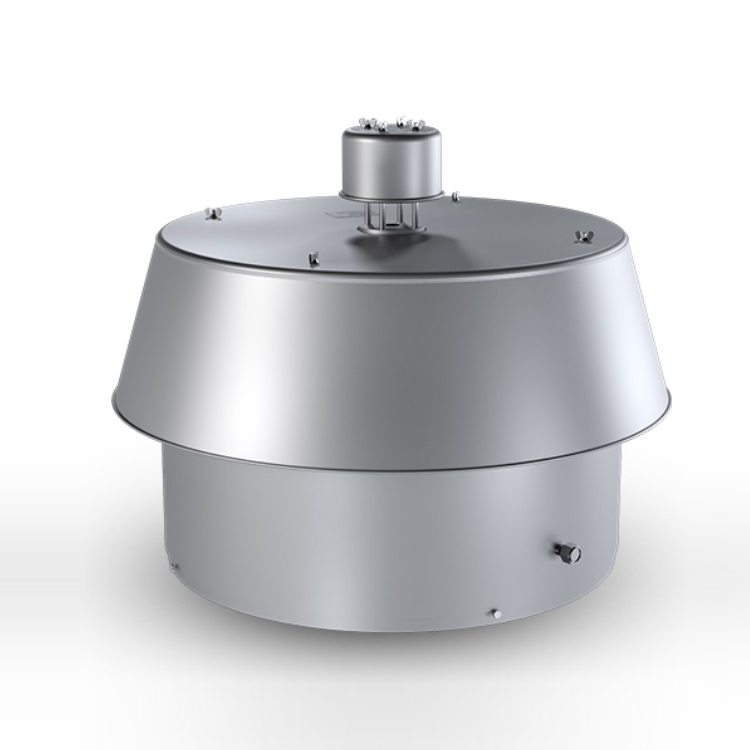

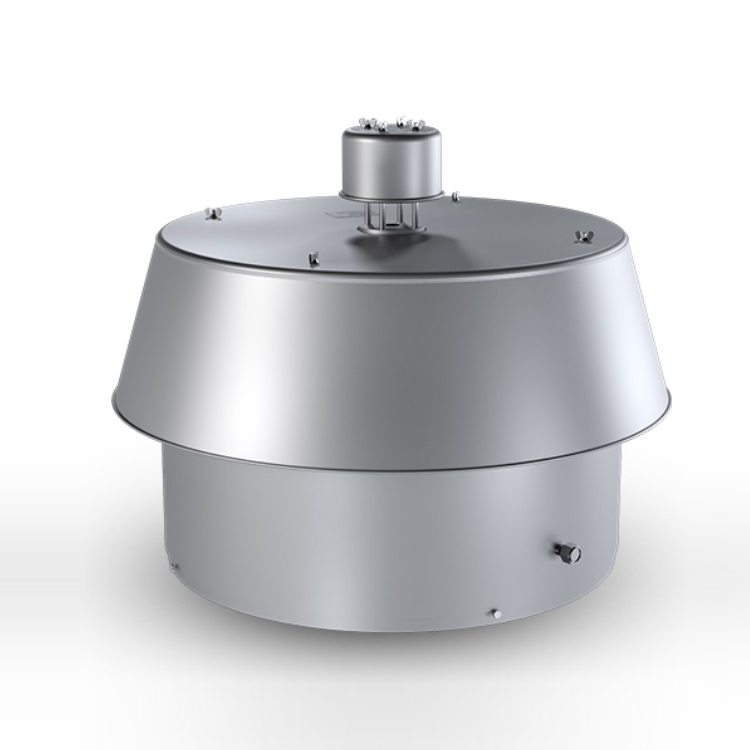

56000 Series PIN-TECH Pressure Relief Vent

Series 56000 Bubble-Tight <500 ppm Pressure Relief Vents are designed and tested to address concerns about the leakage of fugitive emissions prior to set point, and parts per million (ppm) emission rates.

Protectoseal’s PIN-TECH vents are mounted to the vapor space flange connection of a storage tank or vessel. The vents utilize a unique technology that employs a buckling pin to hold the vent piston closed (Fig. 1) with zero leakage up to the relief set point. The pin is an accurately machined, straight metal rod. It is configured to precisely sense transmitted axial forces that are generated as a result of tank pressure. The force required to buckle the pin is governed by Euler’s Law and is a function of the pin’s metallurgy, length and diameter. An exact buckling force can be determined for any specific pin configuration. When the pressure in the tank reaches the vent set point, the axial force is sufficient to buckle the pin and the vent sealing piston is allowed to move to its full open, relieving position (Fig. 2). The pin buckles completely and instantaneously.

• Reduces fugitive emissions of VOC’s mandated by the U.S. Environmental Protection Agency (EPA)

• Fast Inspection, easy maintenance – buckling pin can be quickly replaced

• Sealing capabilities to less than 500 ppm

• Accurate and repeatable set points

• Reduced maintenance costs, far less than those of rupture disks

Datasheet

Datasheet

| Sizes |

: |

2” (DN50) to 24” (DN600). |

| Flange Connections |

: |

ANSI, API or DIN PN16 |

| Materials |

: |

Aluminum, Steel, Stainless Steel and Alloy C/C276 |

| Diaphragm Materials |

: |

FEP, Viton®, Buna N, EPDM, Neoprene |

| Standard Setting Range |

: |

0.75 – 15 PSIG | 51.71 – 1034.21 mbar |

TR

TR

Datasheet

Datasheet

Dudullu OSB, İMES sanayi sitesi B Blok 204.sok No:11 Ümraniye /İstanbul

Dudullu OSB, İMES sanayi sitesi B Blok 204.sok No:11 Ümraniye /İstanbul  +90 216 365 05 54

+90 216 365 05 54  info@dekaproses.com

info@dekaproses.com